Products

Explore

Explore

Energy Storage Battery

Rack mounted energy storage battery 25.6V 200Ah for industry business resident solar power

Cabinet case rack mounted lifepo4 battery 51.2V 100Ah 5kWh for solar energy storage systems

Solar wind power storage systems 51.2V 14kWh 280Ah UPS EPS LiFePO4 battery UL IEC CE

Household backup LiFePo4 battery 51.2V 400Ah M91 PRO

High Voltage Storage Systems LiFePO4 Batteries 614.4 V 100 AH DSE

DSE LiFePO4 614.4 V 200 AH High Voltage Battery Storage Systems

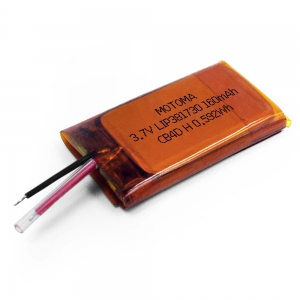

High Temperature LiPo Battery 3.7V 160mAh 0.592Wh

High temperature feature of battery: support the shell-integrated thermoforming process at 110°C for 5 minutes.

Working temperature range: -20~60℃

Nominal Voltage: 3.7 V

Nominal Capacity: 160 mAh

High energy density

Low internal resistance

Sufficient battery capa...

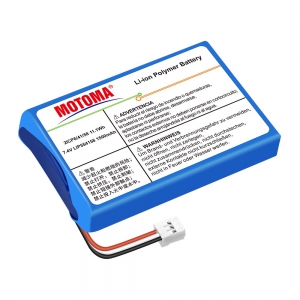

3.7V High Density LiPo Battery 1500mAh

Nominal Voltage: 3.7 V

Nominal Capacity: 1500 mAh

Working temperature range: -20℃ ~ +60℃

High battery consistency

Low internal resistance

Sufficient battery capacity

Outstanding cycle life

Battery Chemistry: Lithium Ion Polymer

Battery Terminations: PC Pins (...

3.7V low temperature li poly battery 150mAh

Working temperature range:-40~60 centigrade

Voltage: 3.7 V

Capacity: 150 mAh

Long cycle life: capacity retention is >80% after 500 times standard cycles

Low internal resistance

Sufficient battery capacity

Outstanding cycle life

Optimized PCM design

In series...

3.7V Fast Charging Lithium Battery 720mAh

Nominal Voltage: 3.7 V

Nominal Capacity: 720 mAh

Working temperature range: -20℃ ~ +60℃

High battery consistency

Low internal resistance

Sufficient battery capacity

Outstanding cycle life

Battery Chemistry: Lithium Polymer

Battery Terminations: PC Pins (Horiz...

Ultra Thin Lithium Polymer Battery 0.9mm

Ultra-thin design.

High energy density.

Long lifespan.

Excellent safety.

Battery Chemistry: Lithium Ion Polymer

Battery Terminations: PC Pins (Horizontal) / (Vertical), SMT (SMD) Mount, Solder Tabs, Wires, Cables with Connectors.

Battery Customizing: Custom design shap...

7.4V High C LiPo Battery 1500mAh

2C Fast discharge

Contiuous high discharge current, low internal resistance,excellent safety

Voltage: 7.4 V

Capacity: 1500 mAh

Low internal resistance

Sufficient battery capacity

Outstanding cycle life

Optimized PCM design

In series connection or in parallel co...

Ultra Thin Lithium Polymer Battery 0.9mm

Ultra-thin design.

High energy density.

Long lifespan.

Excellent safety.

Battery Chemistry: Lithium Ion Polymer

Battery Terminations: PC Pins (Horizontal) / (Vertical), SMT (SMD) Mount, Solder Tabs, Wires, Cables with Connectors.

Battery Customizing: Custom design shap...

LiPo Battery 3.7V Ultra Thin 120mAh

Ultra-thin design.

Nominal Voltage: 3.7 V

Nominal Capacity: 120 mAh

High battery consistency

Low internal resistance

Sufficient battery capacity

Outstanding cycle life

Battery Chemistry: Lithium Ion Poly

Original lipo battery factory from raw material to batter...

3.7V Ultra Thin LiPo Battery 80mAh

Ultra-thin design.

Nominal Voltage: 3.7 V

Nominal Capacity: 80 mAh

Low internal resistance

Sufficient battery capacity

Outstanding cycle life

Optimized PCM design

In series connection or in parallel connection is allowed

Excellent safety.

Battery Chemistry:...

3.7V Fast Charging Lithium Battery 720mAh

Nominal Voltage: 3.7 V

Nominal Capacity: 720 mAh

Working temperature range: -20℃ ~ +60℃

High battery consistency

Low internal resistance

Sufficient battery capacity

Outstanding cycle life

Battery Chemistry: Lithium Polymer

Battery Terminations: PC Pins (Horiz...

3.85V Fast Charging LiPo Battery 110mAh

Nominal Voltage: 3.85 V

Nominal Capacity: 110 mAh

Working temperature range: -20℃ ~ +60℃

Battery Chemistry: Lithium Ion Polymer

High battery consistency

Low internal resistance

Sufficient battery capacity

Outstanding cycle life

Battery Terminations: PC Pins (...

Fast Charging Lithium Polymer Battery 2C 5C

2C~5C fast charging battery.

Charge 70% capacity in very short time.

Long cycle life.

Good consistency, low self-discharge.

None-memory li poly battery.

Excellent safe, environment-friendly.

Battery Chemistry: Lithium Ion Polymer

Battery Terminations: PC Pins (Hori...

3.7V High Density LiPo Battery 1500mAh

Nominal Voltage: 3.7 V

Nominal Capacity: 1500 mAh

Working temperature range: -20℃ ~ +60℃

High battery consistency

Low internal resistance

Sufficient battery capacity

Outstanding cycle life

Battery Chemistry: Lithium Ion Polymer

Battery Terminations: PC Pins (...

11.1V High Density LiPo Battery 2000mAh

Nominal Voltage: 11.1 V

Nominal Capacity: 2000 mAh

Working temperature range: -20℃ ~ +60℃

Sufficient battery capacity

Outstanding cycle life

Optimized PCM design

In series connection or in parallel connection is allowed

Battery Chemistry: Lithium Ion Polymer

...

3.8V High Density LiPo Battery 1300 mAh

Nominal Voltage: 3.8 V

Nominal Capacity: 1300 mAh

Working temperature range: -20℃ ~ +60℃

Excellent safe

Small and light-weight

None-memory battery

Environment friendly battery

High battery consistency

Battery Chemistry: Lithium Ion Polymer

Battery Termina...

3.7V LiPo Battery High Density 7500mAh

Nominal Voltage: 3.7 V

Nominal Capacity: 7500 mAh

Working temperature range: -20℃ ~ +60℃

Excellent safe

Small and light-weight

None-memory battery

Environment friendly battery

Optimized PCM design

In series connection or in parallel connection is allowed

...

3.7V Lithium Polymer Battery High Density 900mAh

Nominal Voltage: 3.7 V

Nominal Capacity: 900 mAh

Working temperature range: -20℃ ~ +60℃

Low internal resistance

Sufficient battery capacity

Outstanding cycle life

Optimized PCM design

In series connection or in parallel connection is allowed

Battery Chemistry...

LiPo Battery High Density 3.7V 6000mAh

Nominal Voltage: 3.7 V

Nominal Capacity: 6000 mAh

Working temperature range: -20℃ ~ +60℃

High battery consistency

Low internal resistance

Sufficient battery capacity

Outstanding cycle life

Battery Chemistry: Lithium Ion Polymer

Battery Terminations: PC Pins (...

Rack mounted energy storage battery 25.6V 200Ah for industry business resident solar power

Rated Power 25.6 V 200 AH (5.12 KWH)

Made By Fresh Grade A Cells

>6000 Cycles @DOD 80%

Intelligent BMS With Advanced Software Improves Performance

Support Parallel Up to 15 Batteries

Max Charging and Discharging Current 150A

Screen For Real-Time Monitoring

Commu...

Cabinet case rack mounted lifepo4 battery 51.2V 100Ah 5kWh for solar energy storage systems

Rated Power 51.2 V 100 AH (5.12 KWH)

Made By Fresh Grade A Cells

>6000 Cycles @DOD 80%

Intelligent BMS With Advanced Software Improves Performance

Support Parallel Up to 15 Batteries

Max Charging and Discharging Current 150A

Screen For Real-Time Monitoring

Commu...

Solar wind power storage systems 51.2V 14kWh 280Ah UPS EPS LiFePO4 battery UL IEC CE

Rated Power 51.2 V 280Ah (14.336 KWH)

Made By Fresh Grade A Cells

7 Years warranty

>8000 Cycles @DOD 80%

Intelligent BMS With Advanced Software Improves Performance

Support Parallel Up to 15 Batteries

Max Charging and Discharging Current 200A

Screen For Real-Tim...

Household backup LiFePo4 battery 51.2V 400Ah M91 PRO

Rated Power 51.2 V 400 AH (20.48 KWH)

Made By Fresh Grade A Cells

>8000 Cycles @DOD 80%

Intelligent BMS With Advanced Software Improves Performance

Support Parallel Up to 15 Batteries

Max Charging and Discharging Current 200A

Colorful Touch Screen With English, Arab...

High Voltage Storage Systems LiFePO4 Batteries 614.4 V 100 AH DSE

Rated Power 614.4 V 100 AH (61.44KWh)

Made By Fresh Grade A Cells

>6000 Cycles @DOD 80%

Intelligent BMS Improves Performance

Support Parallel Up to ? Batteries

Max Charging and Discharging Current 50A

Screen For Real-Time Monitoring

Communication:CAN/RS232

SKU...

DSE LiFePO4 614.4 V 200 AH High Voltage Battery Storage Systems

Rated Power 614.4 V 200 AH (122.88KWh)

Made By Fresh Grade A Cells

>6000 Cycles @DOD 80%

Intelligent BMS Improves Performance

Support Parallel Up to ? Batteries

Max Charging and Discharging Current 100A

Screen For Real-Time Monitoring

Communication:CAN/RS232

S...

Solutions

Solutions